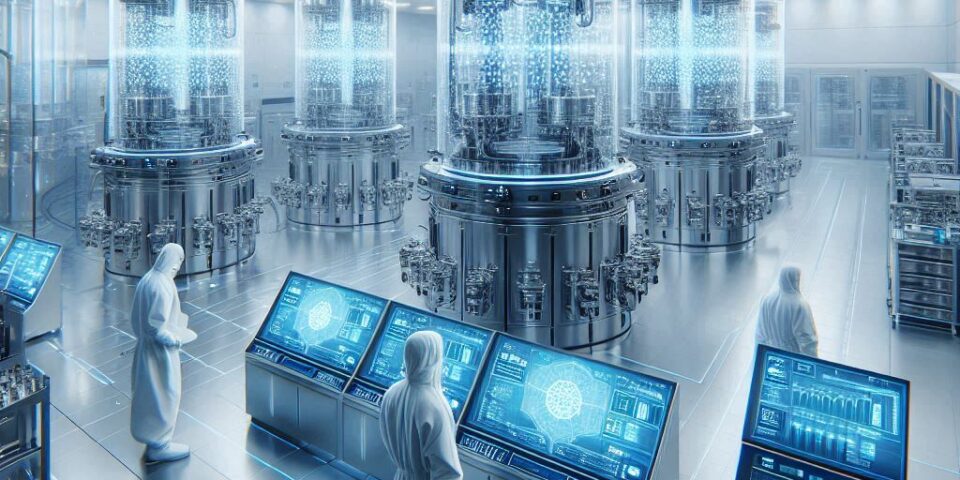

Clean air is critical in the manufacture of safe and effective medicines in the pharmaceutical industry. One of the biggest challenges is cross-contamination: when tiny particles, bacteria, or chemicals from one product or area mix with another, which can compromise the drugs’ quality. Advanced air filtration systems and controlled environments are the different steps undertaken by pharmaceutical organizations to counteract this problem. This is where help from Protech Air comes vital in assuring medicines manufacture in the safest and cleanest environment possible.

The Importance of Cross-Contamination Prevention in Pharma Manufacturing

Cross-contamination is a serious concern in the pharmaceutical industry as it affects product quality, regulatory compliance as well as the safety of patients. It can lead to interrupted operations, recalls, and potential severe health consequences to patients. Regulatory agencies such as the FDA highlight these issues by maintaining that cross-contamination during drug manufacturing violates Good Manufacturing Practices (GMP) and further threatens manufacturer reputation and consumer confidence.

The manufacture of pharmaceuticals means handling very sensitive products, such as oral medicines, injectables, inhalers, and vaccines. Even a small amount of contamination could cause some of these pharmaceutical products to lose their activity or cause toxic effects. This is why rigorous control of environmental parameters such as air quality, pressure differentials, and particulate contamination, must be undertaken in order to ensure the quality and efficacy of the products.

Protech Air’s Advanced Air Filtration Solutions

Protech Air offers market-leading air filtration and cleanroom technology to pharmaceutical companies in their drive toward sterile and contamination-free facilities. Protech provides advanced filtration systems and airflow solutions to achieve the cleanroom standards set forth by GMP, WHO, and FDA. Protech Air enables pharmaceutical companies to achieve very high cleanliness and quality in their production.

1. State-of-the-Art Filtration Technology

Protech Air’s technology focuses on keeping the air as clean as possible. They use powerful HEPA and ULPA filters to remove tiny particles like dust and bacteria, ensuring a contamination-free environment. These high-performance filters catch even the smallest particles, which is crucial in pharmaceutical manufacturing, where even minor contamination can be a big problem.

In addition to this, Protech Air uses advanced activated carbon filters to eliminate odors and harmful chemicals, making the air safer for both the products and the people working in the facility.

2. Precision Airflow Control

The way air flows in pharmaceutical manufacturing is as important as air cleanliness. Protech Air provides airflow management solutions in which airflow direction, speed, and pressure are controlled in important areas. This is very critical in sterile zones, where airflow keeps contaminants from spreading.

Protech Air provides the cleanliness of its clean spaces by sustaining differential air pressure in its areas so that clean spaces are free. The relatively high pressure in these areas forces air out, thus preventing the inward flow of contaminated air. This controlled airflow system greatly minimizes cross-contamination, thereby protecting both products and the manufacture.

3. Monitoring and Real-Time Data

Protech Air’s systems not only filter the air but also monitor it. Protech Air’s Air Quality Monitoring Systems provide continuous real-time measurement of key parameters such as particulate count, temperature, humidity, and airflow velocity. These metrics in real-time allow pharmaceutical companies to ensure compliance with cleanroom regulations and operational requirements.

Through its data logging, Protech Air also provides clients with the ability to create detailed reporting and analytics for internal and regulatory purposes; their abilities in preventing cross-contamination continues to strengthen.

Benefits for Pharmaceutical Manufacturers

1. Enhanced Product Quality

By eliminating the risks of cross-contamination, Protech Air helps pharmaceutical manufacturers produce high-quality, safe products. With a focus on cleanroom integrity, these systems ensure that contaminants are removed before they can affect sensitive pharmaceutical products.

2. Regulatory Compliance

Protech Air’s advanced filtration and airflow systems help pharmaceutical companies adhere to strict guidelines set by regulatory authorities, including GMP and the FDA. Meeting these

regulatory standards is essential for market approval and avoiding potential legal or financial ramifications.

3. Reduced Risk of Product Recalls

Cross-contamination is one of the leading causes of product recalls in the pharmaceutical industry. By implementing Protech Air’s solutions, manufacturers can drastically reduce the chances of contamination, protecting not only their bottom line but also their brand reputation and the trust of consumers.

4. Operational Efficiency

Protech Air’s systems are designed for ease of use, requiring minimal maintenance while delivering maximum effectiveness. This increases operational efficiency and reduces downtime associated with cleaning or repairing filtration equipment, allowing pharmaceutical companies to focus on production without interruptions.

The Future of Pharmaceutical Manufacturing with Protech Air

As the pharmaceutical industry continues to evolve and demand for innovative, life-saving drugs increases, the need for clean, contaminant-free environments becomes even more critical. Protech Air’s commitment to providing reliable, state-of-the-art air filtration solutions will continue to play a vital role in supporting the industry’s efforts to mitigate cross-contamination risks.

With more pharmaceutical companies recognizing the importance of air quality control in maintaining the safety and integrity of their products, Protech Air is set to become an indispensable partner in the sector. By combining cutting-edge technology, regulatory compliance, and industry expertise, Protech Air is ensuring that the pharmaceutical industry’s future remains free from the risks of cross-contamination and focused on advancing health and well-being worldwide.

Conclusion

Cross-contamination is one of the most serious risks faced by pharmaceutical manufacturers today. However, with Protech Air’s state-of-the-art air filtration systems, pharmaceutical companies can confidently mitigate these risks and produce the highest-quality, safest medications for patients worldwide. By investing in advanced filtration and airflow management systems, Protech Air ensures that cleanrooms and controlled environments remain safe and compliant, keeping the pharmaceutical industry on track toward future growth and success.