Maintaining contamination-free environments is critical across industries ranging from pharmaceuticals to semiconductor manufacturing. At the heart of these controlled environments lies a fundamental concept: laminar airflow. Understanding this technology is essential for anyone working with cleanrooms, laboratories, or sterile production facilities.

What is Laminar Airflow?

Laminar airflow, also known as unidirectional airflow, refers to a specific pattern where air moves in parallel layers with consistent velocity and direction. Unlike turbulent or chaotic air movement, laminar flow creates smooth, uniform streams of filtered air that flow in a single direction—typically from ceiling to floor in vertical systems or from back to front in horizontal configurations.

This controlled airflow pattern serves a crucial purpose: efficiently removing airborne contaminants from critical work areas. By maintaining a consistent, unidirectional stream, laminar airflow systems prevent particles, dust, bacteria, and other contaminants from settling on sensitive products, equipment, or work surfaces.

How Laminar Airflow Works

The system operates through strategically positioned High-Efficiency Particulate Air (HEPA) or Ultra-Low Particulate Air (ULPA) filters that remove particles as small as 0.3 microns with an efficiency of 99.997% or higher. Clean, filtered air enters the workspace in a uniform pattern, sweeping contaminants away and directing them toward low-wall air returns or floor-level extraction points.

The air velocity in laminar flow systems typically ranges between 0.3 to 0.5 meters per second (approximately 60-100 feet per minute). This precise velocity ensures adequate particle removal without creating turbulence that could disrupt the controlled environment.

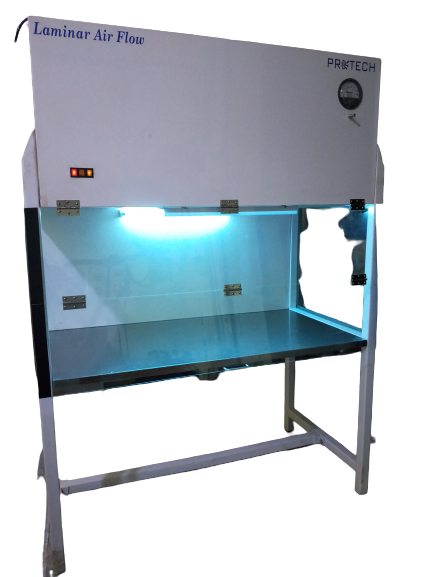

A laminar air flow unit from ProTech Air Systems incorporates advanced HEPA filtration technology to create these controlled environments, meeting international cleanroom standards including ISO Class 5 (Class 100) classifications.

What is the Difference Between Laminar Airflow and Unidirectional Airflow?

While often used interchangeably, “laminar airflow” and “unidirectional airflow” have subtle distinctions worth understanding.

Technically speaking, true laminar flow describes air movement where streamlines remain perfectly parallel without any mixing between layers similar to a smooth-flowing river. This idealized condition is challenging to achieve in real-world cleanroom applications.

Unidirectional airflow is the more accurate term for cleanroom applications. It describes air flowing predominantly in a single direction at a uniform velocity, even if there’s minor turbulence or mixing at the boundaries. Most cleanrooms classified as “laminar flow” actually employ unidirectional airflow systems.

Laminar vs. Turbulent Airflow

The distinction between laminar (unidirectional) and turbulent (non-unidirectional) airflow is fundamental to cleanroom design:

Laminar/Unidirectional Flow:

- Air moves in parallel, uniform layers

- Consistent velocity and direction

- Immediately sweeps particles away from work areas

- Used in ISO Class 1-5 cleanrooms

- Requires extensive HEPA filter coverage (80-100% of ceiling)

- Higher installation and operational costs

Turbulent/Non-Unidirectional Flow:

- Air moves in multiple directions with mixing patterns

- Creates eddies and vortices

- Dilutes contaminants rather than immediately removing them

- Used in ISO Class 6-9 cleanrooms

- Requires less filter coverage

- Lower installation costs and simpler maintenance

For critical applications requiring the highest cleanliness standards, laminar airflow systems provide superior contamination control by preventing particle redistribution and ensuring predictable air movement patterns.

Applications of Laminar Airflow in Cleanrooms

Laminar airflow technology finds extensive applications across industries where contamination control is paramount.

Pharmaceutical Industry

The pharmaceutical sector relies heavily on laminar airflow systems for sterile manufacturing processes. These systems create aseptic environments essential for:

- Sterile drug compounding and filling operations where even minor contamination can compromise product safety and efficacy

- Biological safety cabinets protecting both products and personnel during handling of hazardous materials

- Tablet coating and packaging areas maintaining product purity throughout final processing stages

- Quality control laboratories ensuring accurate testing results free from environmental interference

Pharmaceutical cleanrooms typically operate at ISO Class 5 or better, requiring vertical laminar flow systems with comprehensive HEPA filter coverage to meet regulatory requirements from agencies like the FDA and WHO.

Semiconductor Industry

Semiconductor manufacturing demands extreme cleanliness levels, as even submicron particles can cause defects in microchips and electronic components. Laminar airflow applications include:

- Wafer fabrication facilities where ISO Class 1-3 conditions prevent particle deposition during photolithography and etching processes

- Assembly and testing cleanrooms maintaining product integrity during packaging and final inspection

- Storage areas for silicon wafers and sensitive components requiring dust-free environments

The semiconductor industry often employs 100% HEPA filter ceiling coverage combined with raised perforated flooring to achieve optimal laminar flow conditions and maintain consistent temperatures essential for precision manufacturing.

Biotechnology/Research

Research laboratories and biotechnology facilities utilize laminar airflow to protect sensitive experiments and biological materials:

- Cell culture work requiring sterile conditions to prevent contamination that could invalidate research results

- Genomics laboratories handling DNA/RNA samples vulnerable to environmental degradation

- Microbiology research studying microorganisms under controlled conditions

- Tissue engineering facilities creating sterile environments for regenerative medicine applications

Laminar flow biological safety cabinets are standard equipment in these settings, providing both product protection and personnel safety during handling of potentially hazardous biological agents.

Medical Environments

Healthcare facilities increasingly adopt laminar airflow technology in specific applications:

- Operating theaters creating ultra-clean zones around surgical sites to reduce infection risks during complex procedures like orthopedic surgeries

- Compounding pharmacies preparing custom medications under sterile conditions

- Hospital laboratories conducting diagnostic testing requiring contamination-free conditions

- Medical device manufacturing ensuring implantable devices remain sterile throughout production

While complete laminar flow operating rooms are less common due to high costs, localized laminar flow systems over operating tables provide targeted protection where it matters most.

Benefits of Laminar Airflow in Cleanrooms

Implementing laminar airflow systems delivers numerous advantages for contamination-critical operations:

Superior Contamination Control: The unidirectional flow pattern immediately sweeps particles away from work surfaces, preventing settling and accumulation. This creates consistently clean conditions essential for quality assurance.

Predictable Air Movement: Unlike turbulent systems where contaminant distribution is chaotic, laminar flow provides predictable particle trajectories, allowing operators to position themselves and equipment optimally.

Product Protection: The constant stream of HEPA-filtered air creates a protective envelope around sensitive products, minimizing exposure to airborne contaminants during critical manufacturing or research procedures.

Regulatory Compliance: Many industries face strict regulatory requirements for air quality. Laminar flow systems help facilities meet ISO 14644 standards, FDA guidelines, and other international regulations governing cleanroom operations.

Reduced Cross-Contamination: The unidirectional flow prevents contaminants from one area being transported to another, crucial in multi-product facilities or research environments handling different samples.

Enhanced Process Reliability: Consistent environmental conditions lead to more reproducible results in research and manufacturing, reducing batch failures and improving overall yield rates.

Personnel and Product Safety: In applications involving hazardous materials, laminar flow biological safety cabinets protect both operators and the environment while maintaining product sterility.

The Bottom Line

Laminar airflow represents a cornerstone technology for industries requiring stringent contamination control. By creating smooth, unidirectional air streams through HEPA/ULPA filtration, these systems provide the cleanest possible working environments for pharmaceutical production, semiconductor manufacturing, biotechnology research, and medical applications.

While laminar flow systems require higher initial investment and ongoing operational costs compared to turbulent airflow alternatives, the benefits superior contamination control, regulatory compliance, product protection, and process reliability—make them indispensable for critical applications where even microscopic contamination can have significant consequences.

Whether you’re designing a new cleanroom facility or upgrading existing infrastructure, understanding the principles and applications of laminar airflow helps you make informed decisions about creating optimal controlled environments. Partnering with experienced laminar air flow unit manufacturers ensures your facility receives properly designed, validated systems that meet your specific industry requirements and regulatory obligations.

For industries where quality, safety, and precision are non-negotiable, laminar airflow technology continues to set the standard for contamination control in the 21st century.

Q: What is the difference between laminar and turbulent airflow?

A: Laminar airflow moves in parallel uniform layers with consistent velocity, immediately removing particles. Turbulent airflow moves in multiple directions with mixing, diluting rather than removing contaminants.

Q: What industries use laminar airflow systems?

A: Pharmaceutical manufacturing, semiconductor fabrication, biotechnology research, medical device production, and hospital operating rooms.

Q: How much does a laminar air flow unit cost?

A: LAF units range from ₹2,00,000 to ₹15,00,000+ depending on size, configuration (vertical/horizontal), and cleanroom class requirements.

Q: What is the air velocity in laminar flow systems?

A: Typically 0.3 to 0.5 meters per second (60-100 feet per minute) to ensure particle removal without creating turbulence.

Q: How often should HEPA filters be replaced?

A: Every 6-12 months depending on usage and environmental conditions, or when pressure drop increases significantly.