Air quality has become more critical than ever in 2025, especially in industrial and commercial spaces across Gujarat and India. Whether you’re managing a pharmaceutical facility in Ahmedabad, a hospital in Surat, or a manufacturing plant anywhere in India, understanding AHU (Air Handling Unit) filters is essential for maintaining optimal indoor air quality and operational efficiency.

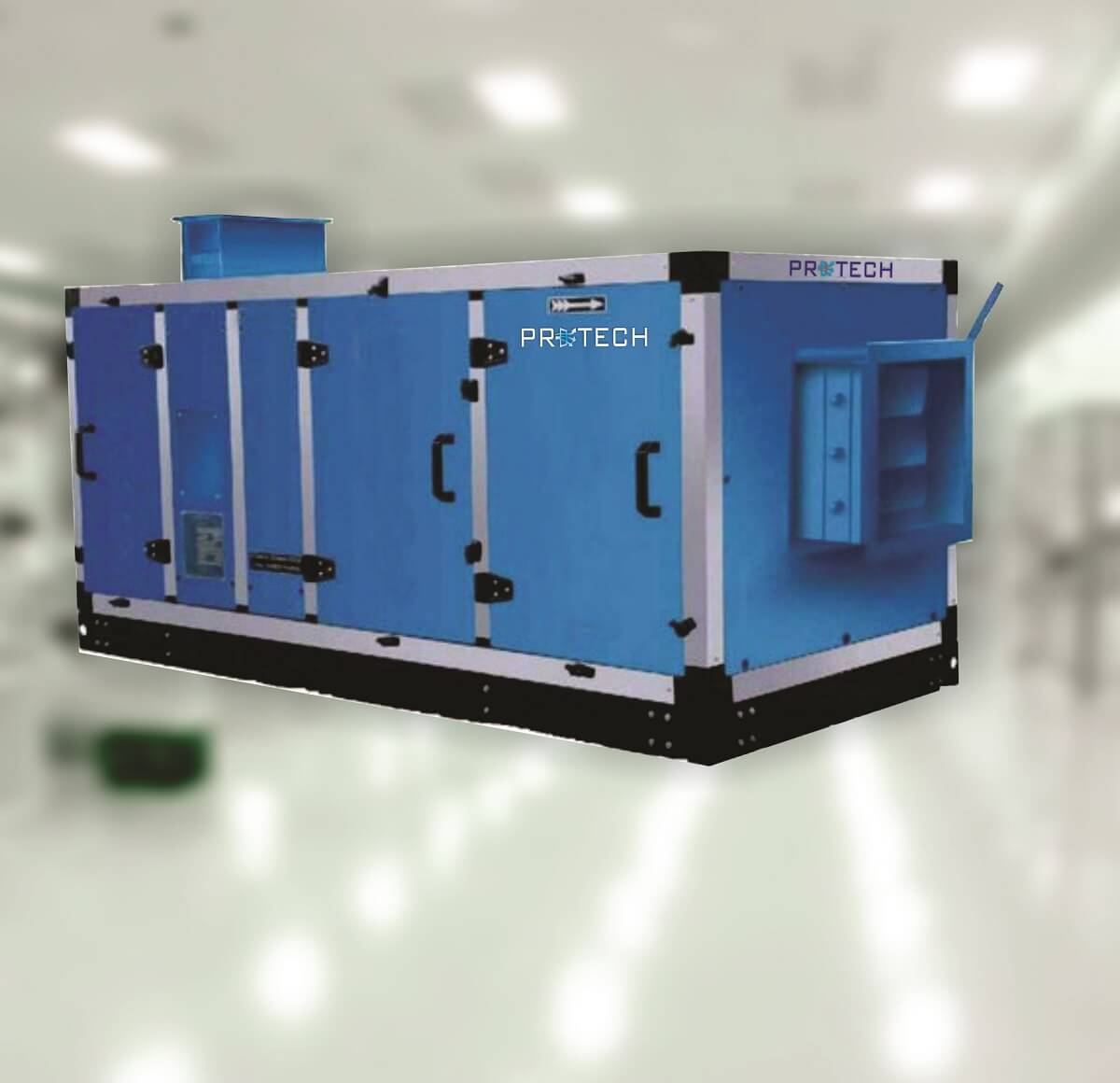

As a leading AHU filter manufacturer in Ahmedabad with over a decade of experience, Protech Air Systems has compiled this comprehensive guide to help facility managers, HVAC professionals, and business owners make informed decisions about their air filtration needs.

What Are AHU Filters and Why Are They Critical?

AHU filters are specialized filtration components designed to remove airborne contaminants from the air circulating through your HVAC system. These filters serve as the first line of defense against dust particles, bacteria, volatile organic compounds (VOCs), and other harmful pollutants that can compromise indoor air quality.

For air handling units, the filters must be changed after a period of operation, in order to improve efficiency and IAQ. This regular maintenance is crucial for maintaining system performance and ensuring healthy indoor environments.

The Growing Importance of Air Filtration in India

In today’s post-pandemic world, businesses across Ahmedabad and Gujarat are increasingly prioritizing indoor air quality. The pharmaceutical industry, which forms a significant part of Gujarat’s economy, particularly requires high-efficiency filtration systems to maintain cleanroom standards and GMP compliance.

Complete AHU Filter Types Guide: Which One Do You Need?

Understanding different filter types is crucial for optimal air quality management. Let’s explore each category in detail:

1. Pre-Filters (G3, G4 Class) – Your First Line of Defense

Primary Function: Remove large dust particles and debris

Efficiency Rating: 80-90% for particles ≥10 microns

Typical Applications: Commercial buildings, shopping malls, initial filtration stage

Pre-filters are essential for protecting downstream filters and extending their lifespan. In dusty environments like construction sites or manufacturing facilities in Gujarat, these filters prevent larger particles from clogging more expensive fine and HEPA filters.

Key Benefits:

- Cost-effective initial filtration

- Extends life of downstream filters

- Easy maintenance and replacement

- Suitable for most commercial applications

2. Fine Filters (M5, M6 Class) – Medium Efficiency Filtration

Primary Function: Capture smaller particles and some microorganisms

Efficiency Rating: 60-80% for particles ≥1 micron

Typical Applications: Pharmaceutical facilities, food processing, office buildings

Fine filters provide the crucial middle stage of filtration, particularly important in pharmaceutical manufacturing facilities across Ahmedabad where maintaining controlled environments is mandatory.

3. HEPA Filters (H13, H14 Class) – Ultra-High Efficiency

Primary Function: Remove 99.97% of particles ≥0.3 microns

Efficiency Rating: H13 (99.95%), H14 (99.995%)

Typical Applications: Cleanrooms, hospitals, research laboratories

HEPA filters represent the gold standard in air filtration technology. Our ISO 16890 certified HEPA filters are essential for:

- Pharmaceutical cleanrooms maintaining ISO 14644 standards

- Hospital operating theaters and ICUs

- Research laboratories requiring sterile environments

- Electronics manufacturing facilities

4. Activated Carbon Filters – Gas and Odor Removal

Primary Function: Absorb harmful gases, VOCs, and odors

Efficiency Rating: Highly effective against chemical contaminants

Typical Applications: Industrial facilities, chemical processing, indoor air treatment

These specialized filters are crucial for industries dealing with chemical processes, paint booths, or any application where gas-phase contaminants need removal.

AHU Filter Replacement Schedule: When and How Often?

Based on real situations and conditions, the lifespan of the AHU filter is changed. But we recommended that it is better to replace your AHU filter for 90 days or 3 months. Generally, AHU air filters should be replaced every 3-6 months, though this can vary based on usage and air quality conditions.

Recommended Replacement Intervals

Pre-Filters (G3/G4):

- Standard environments: Every 3-6 months

- High-dust environments: Every 1-3 months

- Light commercial use: Every 6-9 months

Fine Filters (M5/M6):

- Pharmaceutical facilities: Every 6-12 months

- Commercial buildings: Every 9-12 months

- Critical environments: Every 4-6 months

HEPA Filters (H13/H14):

- Cleanroom applications: Every 12-18 months

- Hospital environments: Every 12-24 months

- Laboratory settings: Every 18-24 months

Activated Carbon Filters:

- Industrial applications: Every 6-12 months

- VOC-heavy environments: Every 3-6 months

- General odor control: Every 12-18 months

Signs Your AHU Filter Needs Immediate Replacement

Signs a filter needs replacement include reduced airflow, visible dirt buildup, increased energy use, or complaints about air quality.

Watch for these indicators:

- Pressure differential exceeding manufacturer specifications

- Visible dirt accumulation on filter surface

- Reduced airflow from supply vents

- Increased energy consumption

- Employee complaints about air quality

- Unusual odors in conditioned spaces

Step-by-Step AHU Filter Replacement Guide

Pre-Replacement Preparation

- Safety First: Turn off the AHU system and ensure electrical safety

- Document Current Setup: Take photos of existing filter arrangement

- Check Specifications: Verify filter dimensions and efficiency ratings

- Gather Tools: Have proper handling equipment ready

Replacement Process

- Access the Filter Section: Remove access panels carefully

- Remove Old Filters: Handle used filters as contaminated material

- Inspect Filter Housing: Check for damage or bypass leakage

- Install New Filters: Ensure proper orientation and sealing

- System Restart: Follow proper startup procedures

Post-Installation Checklist

- Verify pressure differential readings

- Check for air bypass around filters

- Monitor initial system performance

- Document replacement date and filter specifications

How to Choose the Right AHU Filter for Your Application

Key Selection Criteria

1. Application Requirements

- Industry standards (GMP, ISO 14644, etc.)

- Particle removal efficiency needed

- Gas-phase contamination concerns

- Energy efficiency requirements

2. Environmental Factors

- Local air quality conditions

- Seasonal variations in Gujarat

- Indoor contamination sources

- Humidity and temperature conditions

3. System Considerations

- Available pressure drop budget

- Filter housing dimensions

- Maintenance accessibility

- Replacement frequency preferences

Industry-Specific Requirements

Pharmaceutical Industry:

- HEPA filters for critical areas

- Pre-filters for equipment protection

- Carbon filters for chemical processes

- Compliance with regulatory standards

Healthcare Facilities:

- High-efficiency particulate removal

- Antimicrobial filter options

- Proper filtration for different zones

- Emergency backup considerations

Commercial Buildings:

- Balance between efficiency and energy consumption

- Occupant comfort and health

- Maintenance cost considerations

- Indoor air quality compliance

Cost Optimization Strategies for AHU Filters

Total Cost of Ownership Analysis

Consider these factors when evaluating filter costs:

- Initial purchase price

- Replacement frequency

- Energy consumption impact

- Labor costs for maintenance

- Downtime during replacements

Money-Saving Tips

- Bulk Purchasing: Order filters in larger quantities for better pricing

- Preventive Maintenance: Regular inspections prevent emergency replacements

- Energy Efficiency: Choose filters with optimal pressure drop characteristics

- Staff Training: Proper installation reduces premature failures

Protech Air Systems: Your Trusted AHU Filter Partner in Ahmedabad

As a leading AHU filter supplier in Ahmedabad and across Gujarat, Protech Air Systems offers:

Why Choose Protech Air for Your AHU Filter Needs?

Manufacturing Excellence:

- ISO 16890 certified production facility

- State-of-the-art testing equipment

- Stringent quality control processes

- Custom sizing capabilities

Comprehensive Product Range:

- All filter classifications (G3 to H14)

- Standard and custom dimensions

- Various media options

- Special applications support

Expert Support:

- Technical consultation services

- Installation guidance

- Maintenance training

- 24/7 customer support

Local Advantage:

- Quick delivery across Gujarat

- Local technical support

- Understanding of regional requirements

- Competitive pricing for bulk orders

Future Trends in AHU Filtration Technology

Smart Filter Monitoring

Integration of IoT sensors for real-time filter condition monitoring, predictive maintenance scheduling, and automated replacement alerts.

Advanced Filter Media

Development of antimicrobial filters, higher efficiency materials, and sustainable filter options for environmental responsibility.

Energy-Efficient Designs

Focus on reducing pressure drop while maintaining filtration efficiency, contributing to overall HVAC system energy savings.

Conclusion

Proper AHU filter selection, maintenance, and replacement are critical for maintaining healthy indoor environments across Gujarat’s diverse industrial landscape. Whether you’re managing a pharmaceutical facility in Ahmedabad, a hospital in Vadodara, or a commercial complex in Surat, understanding these fundamentals will help you make informed decisions that protect both your facility and its occupants.

Remember that effective air filtration is an investment in operational efficiency, regulatory compliance, and occupant health. Partner with experienced professionals like Protech Air Systems to ensure your AHU filtration system delivers optimal performance year-round.

For expert consultation on your specific AHU filter requirements, contact Protech Air Systems today. Our technical team is ready to help you design the perfect filtration solution for your unique application.